100 Watt

Gulf States Saw & Machine Co., FM1212-50S is able to engrave acrylic.

The enclosure comes with a motorized door. It works with FSL Muse Pandora installed on a desktop.

In an optical fiber laser, the light is bent by refraction. An optical fiber cable passes the light through an impurity-free transparent silica glass core. The core is covered with cladding, another layer of silica doped with added materials for lowering its refractive index. Because of their refractive index difference, the light will get refracted at the core-clad interface.

The heart of a fiber laser's operation is its laser source. They do not contain any gaseous material like a CO2 laser.

All kinds of materials can be cut with laser machines. It is dependent on which type of laser machine your have that will allow you to cut different materials. Laser machines that use CO2 can't cut through reflective metallic materials such as brass, copper and aluminum. However, they are capable of cutting through nonmetallic materials like plastic and wood.

2022 best budget small metal laser cutter ST-FC1390 adopts fiber laser generator, fully enclosed design, environmental friendly in all types of sheet metal cutting, which is a compact entry level fiber laser cutting system for hobbyists in small business with metal signs, metal tags, metal logos, metal letters, and metal jewelry, now the hobby fiber laser metal cutting machine for sale at a low price.

Gulf States Saw & Machine Co., FM1212-50S is able to engrave acrylic.

The enclosure comes with a motorized door. It works with FSL Muse Pandora installed on a desktop.

MCWlaserPRO laser engraver offers three different versions. There are 20W (30W), and 50W options. These lasers operate at 1064nm wavelength.

What it means is, when working with materials like metals that reflect laser beams, they will absorb fiber laser light at a much higher rate than laser light generated by CO2 lasers.

Fiber lasers are solid-state lasers used widely in laser marking and engraving machines. The major difference between a fiber laser and a CO2 laser lies in their ability to laser cut sheet metal.

Fiber lasers have a very small focal point which makes it impossible to cut through thick materials with them. In these cases, a CO2 Laser is the best option.

You can mount Muse Pandora under an adjustable work desk, as shown below, for effective engraving when using such lenses.

MCWlaser PRO includes a Z-axis. It can be moved manually with a control knob. Unfortunately, the XY and Z axes can't be adjusted.

The one thing you should know is that fiber lasers have a limited work-bed size and can only cut certain materials.

To expand the engraving area, longer focal length lenses can be used. These lenses require high concentrated power and are taller.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

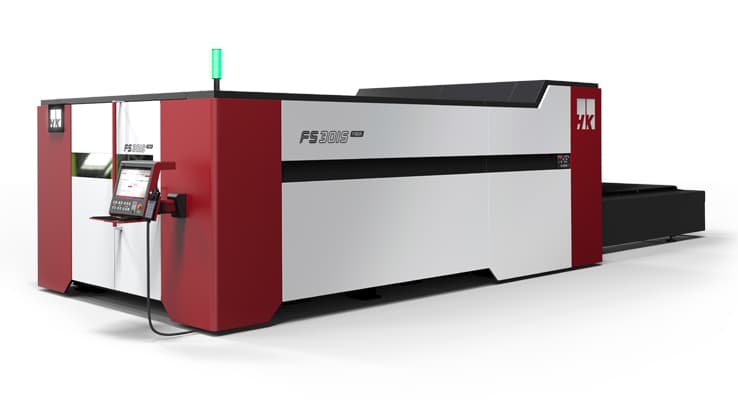

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.

Thin carbon fiber mat can be cut with some fraying - but not when coated. The laser can cut or etch. The laser can cut materials such as wood, paper, cork, and some plastics.